70% of businesses which suffer a major fire never re-open and electrical faults are the main cause of workplace fires. How can thermal imaging help protect your business?

Thermal imaging cameras allow a visible representation of temperature, enabling the early identification of hotspots which could develop into electrical fires.

Fundamentally, electrical fires are the result of localised overheating caused by poor connections, insulation failure, failing components, wiring mistakes and circuit overloading.

Thermal imaging technology identifies heat spikes which indicates energy loss, missing or defective insulation, and can also indicate leaks and find moisture which is hazardous to electrical equipment. The electrical industry was one of the first to embrace the use of thermal imaging cameras as a means of reducing fire risk, although many other industries have now adopted this technology.

Thermal imaging equipment can detect extremely small temperature differences and produce an image with a high level of resolution to help pinpoint the source of problems easily.

As images can be taken through solid surfaces such as walls or protective enclosures, a thermal survey can be completed without any intrusive building work.

Whilst there is no specific legal requirement for thermal imaging, it is being increasingly requested by insurance companies, as they recognise the important role of thermal imaging in preventative maintenance and achieving compliance with the Electricity at Work (1989) Regulations.

Aviva Commerical Insurance highlights the importance of thermal imaging which they describe as “A non-invasive way of identifying minor and major faults – an efficient complement to a full electrical testing programme. Can identify faults before equipment fails and helps manage production downtime / keeps business disruption to a minimum”.

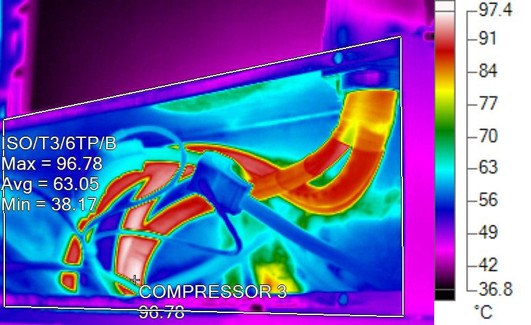

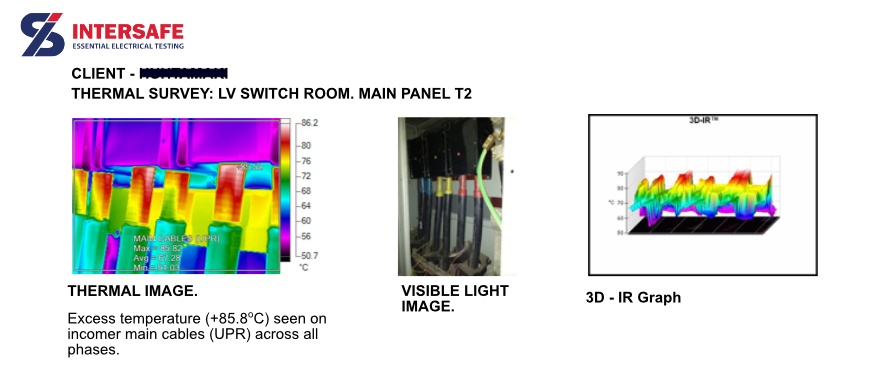

The above images are an extract from a thermal survey conducted by Intersafe. As a result of incomplete electrical maintenance and testing over a number of years, temperatures of 86C were recorded in the main supply panel which had to be replaced at a significantly expense to avoid a near-certain electrical fire.

Concerned about a part of your electrical installation? Contact Intersafe